Hakko WICK/Desoldering Wire

Desoldering wire/wick are copper braids that are used to remove solder from components on a printed circuit board (PCB).

While desoldering wires are usually pre-fluxed, Hakko provides 3 types to cater to different uses:

- Unfluxed: Untreated copper braid spooled on an ESD safe bobbin

- No-clean: Halogen-free low-residue flux coated copper braid spooled on an ESD safe bobbin

- Regular: Rosin flux treated copper braid

How to remove solder with the desoldering wire

- Apply flux to the joint to be desoldered

- Place the desoldering wire onto the joint, and place the soldering iron on the wire.

- The soldering iron melts the solder, which is then pulled into the desoldering wire. Once the solder has been removed, lift the wire and iron off the board at the same time.

Tips for effective removal

While it may seem easy to use, the wrong techniques may cause unnecessary thermal damage to the PCB or the components. Extended contact of the soldering iron to the board or component may cause thermal damage. If the solder is not being removed by the desoldering wick, try out the steps below!

- Apply a small amount of solder to the joint.

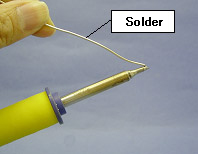

- Apply a small amount of solder at the tip of the soldering iron.

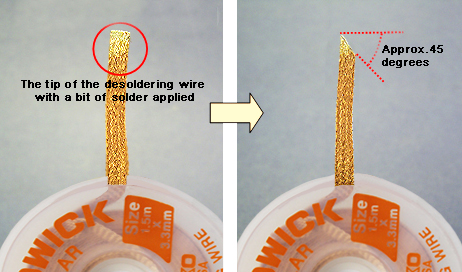

- Apply a small amount of solder at the tip of the desoldering wire to aid easier removal.

- Cut the soldered tip of the wire at an angle of 45 degrees (ensure that the solder at the tip is not cut off).

By applying a small bit of solder onto the joint, tip or desoldering wire, it helps to cut the surface tension and allow the solder from the joint to be absorbed easily by the wire.

If it is necessary to cut the wire during the desoldering process, cut it at 45 degrees again with solder still remaining. It also helps to trim the wire when it is has been saturated with solder and cannot absorb anymore.

Check out Hakko's Desoldering Wires/Wicks here!