Skip to product information

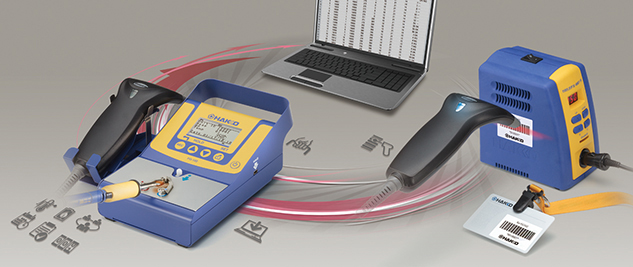

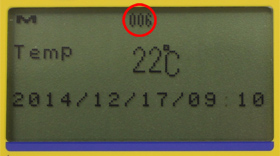

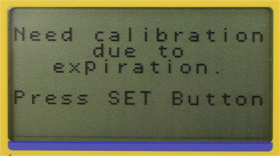

FG-102 Thermometer with Traceability Management with Calibration

$1,210.00 SGD

Availability: Pre-Order ONLY. Lead Time: 8-16 Weeks