Connecting a ground wire to Hakko FT-710

Electrostatic Discharge (ESD) seems small but can cause great damage especially when working with electronics. To reduce ESD in your work place, it is essential to ground all tools and equipment, allowing the static charge to dissipate.

Apart from Hakko's wide range of ESD-safe products, some soldering accessories can be grounded with the use of a grounding wire, such as the FT-710 Tip Cleaner.

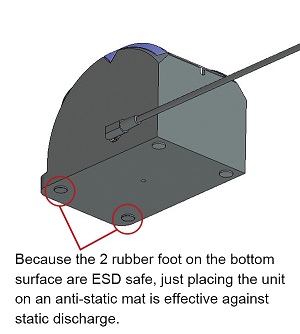

A grounding wire (to be purchased separately) can be connected at the back of the FT-710 tip cleaner with a screw. In addition, the two rubber foot located at the bottom of the FT-710 are ESD safe, which means that static electricity can be reduced by placing the device on an anti-electrostatic mat.

Why do we need to remove ESD?

- Protect individuals from the dangerous electric-shock voltage

- Stabilize voltage levels to prevent explosive hazard

- Prevent electronic components from short-circuiting

Learn more about ESD here

Learn about how ESD can damage your electronics here