Long term usage of the soldering iron and accumulation of the oxides on the enclosure pipe or tip can cause voltage to leak as wear and tear occurs. During the soldering process, a voltage leak can cause harmful effect to the PCB and the device. Therefore, it is important to check the leak voltage periodically.

The lower the leak voltage, the better. All HAKKO soldering stations have been configured to have a leak voltage set to 2mV or less in conformance to the MIL standard.

Measuring Leak Voltage

- Use the FG-101B to measure the leak voltage.

- Set to the highest temperature before measuring the leak voltage.

By setting to the highest temperature, the thermometer can record the highest leak voltage. If normal results are obtained when set to the highest temperature, other temperature settings will obtain normal results as well.

MIL Standard: 2mV or less

How to Reduce Leak Voltage?

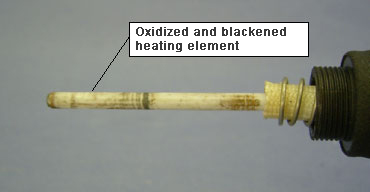

1. Replace the heating element when it is oxidized.

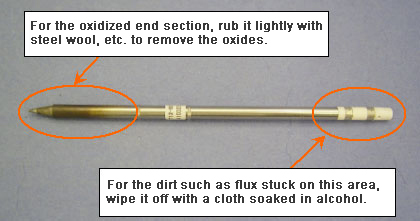

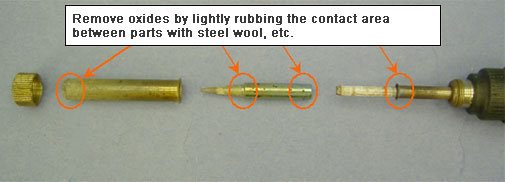

2. Remove oxides with steel wool or fine-grade sandpaper

*As an oxidized tip can reduce tip wettability, clean the tip with FS-100 to remove oxidation.