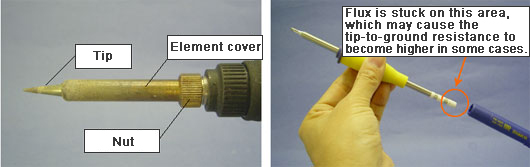

Oxides and flux left on the tip, element cover, and nut can cause tip-to-ground resistance to increase, which results in an increased leak voltage. Therefore, it is important to measure the tip-to-ground resistance regularly.

As with leak voltage, a lower tip-to-ground resistance is preferred.

All HAKKO soldering stations have the resistance set to 2Ω or less which is stricter than that of the MIL standard of 5Ω or less.

Measuring Tip-To-Ground Resistance

- Use the FG-101B to measure the tip-to-ground resistance

- Let the current temperature of the soldering iron stabilize to the set temperature before measuring

How to Reduce Tip-To-Ground Resistance?

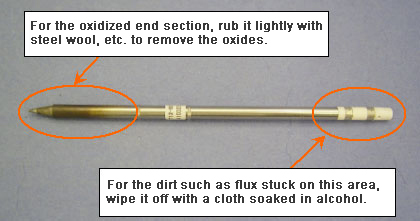

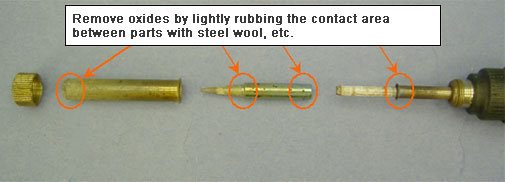

1. Remove oxides with steel wool or fine-grade sandpaper

*As an oxidized tip can reduce tip wettability, clean the tip with FS-100 to remove oxidation.